All successful companies work actively on becoming more competitive in one way or another. This can involve anything from market visibility and product development to logistics solutions and cost-efficiencies.

The role of the production organization in the business transaction with the customer consists in producing the right amount to the right quality at the right time. To a large extent, therefore, the areas where production looks for improvements are quality assurance and enhancement, delivery precision and control of costs.

It is after all a fact that the contribution of the production organization to a profit/ loss calculation is in principle limited to costs. Revenue of course varies over time, but revenue per sold and delivered unit is a parameter that is established from the business agreement with the customer – an agreement signed by someone else on some other occasion.

It is therefore important to know not only that you are delivering the right quality at the right time to your customer, but that you are doing so at the lowest possible cost. The margin that arises is profit, and this can be reinvested to give you still greater competitive edge.

The impact of production disturbances on the financial aspects

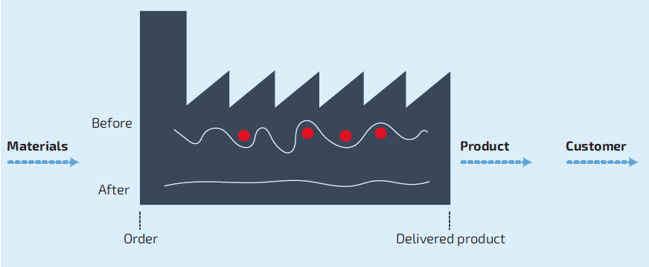

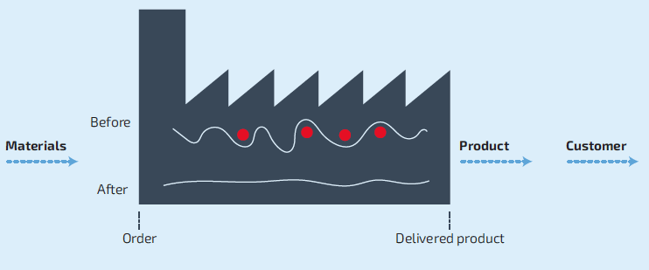

The diagram above illustrates a very general production set-up. You invest in materials that are processed and refined in machines and equipment (these are also investments). This is done with the aid of staff to whom you pay wages. The process takes place in premises that cost money. The whole set-up is surrounded by an administration whose job it is to ensure that, over the long term, everything is done at the right time, to the right quality and at as low a cost as possible.

Out of the production set-up come products that can be delivered to customers who pay a previously agreed price.

The production organization’s financial results are revenue minus costs. But, precisely because it is a production set-up, the only thing we can influence are the costs. The revenue has already been fixed previously in the agreement with the customer.

Throughout the entire production flow, costs arise when we use resources. Some of the resources used go towards processing (refining) the product. Other resources used do not (unfortunately).

In order for the production to be profitable financially, the degree of refinement in the processing must be greater than the amount of resources used. This is where you earn money. The more you can reduce the amount of resources used without affecting the agreement with the customer, the more profitable your set-up. The problem is that, throughout the entire flow, resources are used that neither create value nor result in refinement. We call this waste. However, as a production manager, it is difficult to get a good picture of the disturbances. It is not unusual for production to take place round the clock, whereas you yourself work during the day, and a lot of your time is taken up with meetings and admin.

By measuring, visualizing and communicating waste in an objective manner, you can identify those disturbances that represent “turning buoys” and create work without creating value for the customer.

Only once you have identified the “turning buoys” can you effectively apply measures to reduce use of resources that does not create value for the customer This will reduce costs and increase profitability.

If there is a common approach to problems and disturbances from operators and technicians through to production engineering, quality and planning, the work of the production management team in terms of assigning priorities is made a lot easier.

When there is agreement in the organization on a fact-based decision basis, improvement resources can be focused on actual measures instead of on collecting data, comparing it and discussing it.

Long-term profitability is not achieved by doing the same thing as before but at greater speed. It is achieved rather by not devoting time and resources to anything that does not create value for the customer.

This means that, in the final analysis, the customer gets the same product with the same features, but we in production have used fewer resources on the way.

OEE is the tool for measuring efficiency and disturbances. A correctly implemented OEE-measurement will

- Highlight waste, disturbances and improvement potential so that these become visible to all

- Reduce waste and disturbances and use fewer resources per produced unit

- Increase resource efficiency