Recent data from Sinf for Q2-Q3 2023 reveals a concerning deceleration in the Swedish industrial sector. Profits are down by 10% from the 15-year average, and 60% of businesses have either stagnant or reduced revenues from the previous quarter.

Sanna Arnfjorden Wadström, Sinfs' CEO, emphasises the need for technological shifts to reverse the trend. Interestingly, 42% of businesses report having automated half their production, but only 25% did so in the last three years. Additionally, 80% have digitised in this period.

A need for more capital for modernisation, significantly to reduce energy use, is evident. Regional investment aids are available, but their limited scope might foster uneven competition among Swedish firms.

However, 57% state that they have difficulty finding trained manpower, 23% plan to hire, 66% assess that Sweden is heading into or currently in a recession, and 42% continue to be affected by material shortages.

How RS Production can help

This is a great opportunity for your factory. RS Production empowers teams to run more predictable, profitable, and sustainable factory operations. How?

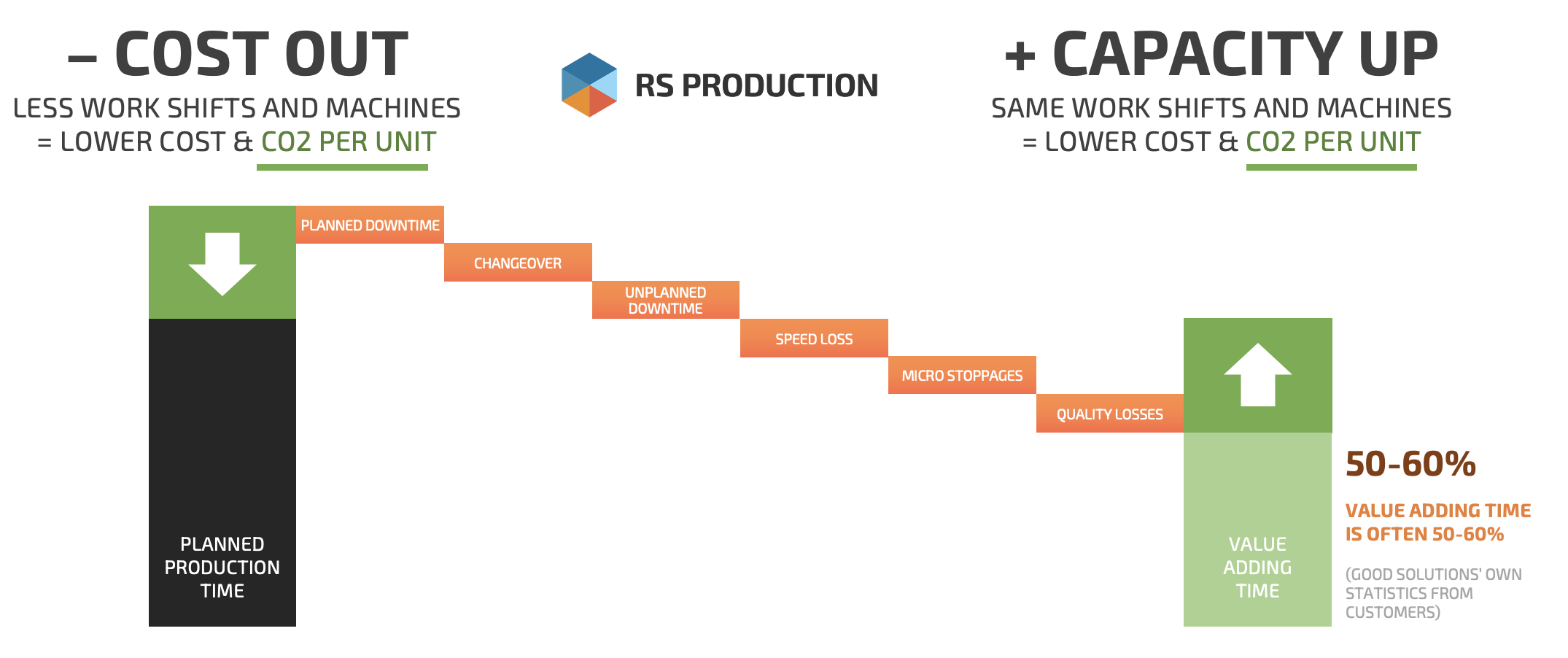

- Identify and minimise production losses: Understand where you're leaking productivity and plug those gaps.

- Optimise resource usage: Consume less machine time, labour, and electricity, and emit fewer CO2 emissions.

- Maintain standards and reduce quality losses: Ensure all processes are followed, making operations seamless.

All this combined help you do more with less. You choose if the target is to produce the same amounts using fewer resources or manufacture higher volumes using the same resources as you currently do.

Either way, your action-taking empowered by RS Production will help your factory become more profitable and sustainable – without significant investments in new machinery or people.

Too good to be true? Find out for yourself and see real-world examples from some of our 200+ factory customers worldwide

Book a free 30-minute online meeting with a Good Solutions expert and delve deeper into how RS Production can reshape the future of your factory operations and understand your ROI.

Let's make every production minute count.