In the competitive manufacturing world, factories constantly seek ways to reduce costs and increase efficiency. Yet, many overlook a hidden drain on profitability - energy inefficiency. Research from Mälardalens University reveals that industrial machinery uses 20 to 80% of its energy while idling, leading to significant energy losses. This impacts your bottom line and contributes to a larger carbon footprint.

The transformative power of OEE and energy monitoring

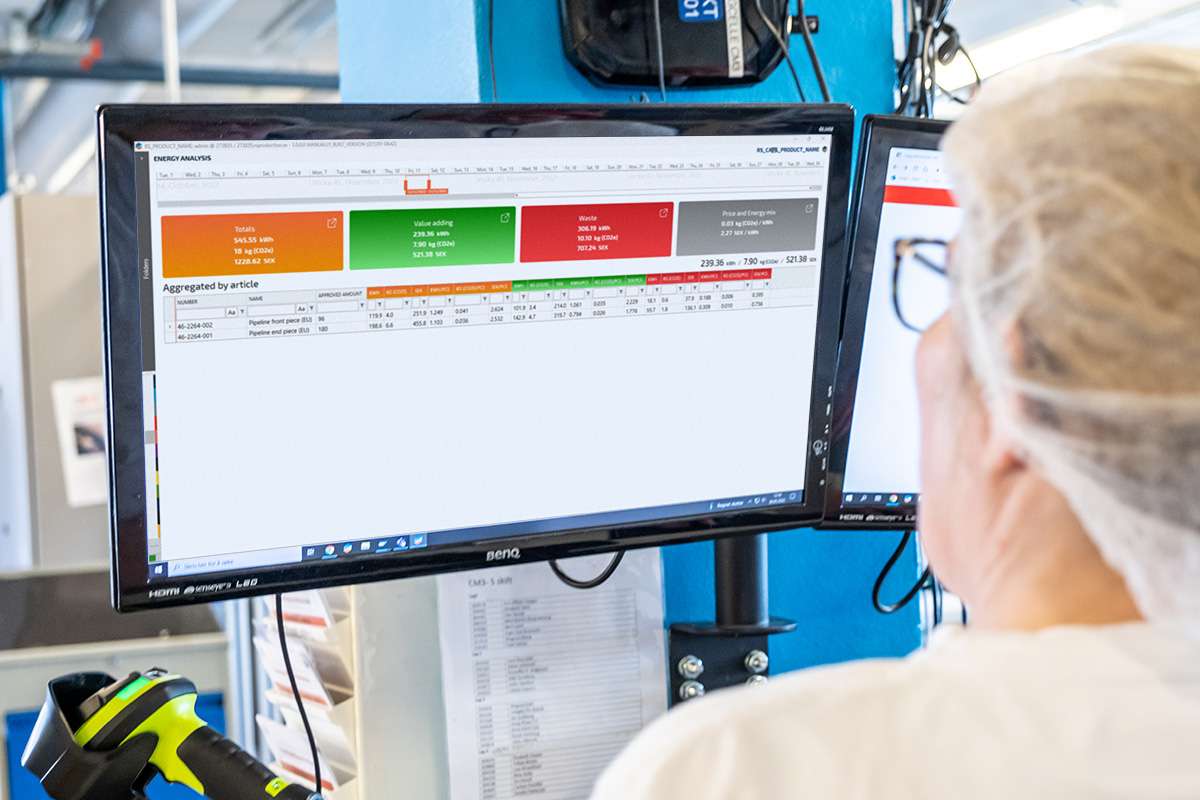

Imagine a world where your factory could significantly reduce energy use, lower costs, and improve sustainability. This is not a distant dream but a tangible reality made possible by combining an Overall Equipment Effectiveness (OEE) system with energy monitoring.

These tools provide the means to measure and visualise energy use, potentially lowering it by 15-20%. They also help factories understand energy losses per article, unit, and other stop reasons, including those due to machinery idling. This empowers factories to focus on reducing significant energy-related costs and CO2e waste to a minimum.

The path to sustainability and profitability

The journey from energy inefficiency to sustainability and profitability is more manageable than it may seem. The focus on energy efficiency reduces your environmental footprint and leads to cost savings and enhanced profitability.

It's quick and easy to start measuring your machinery's energy consumption. The standard ampere meters connect seamlessly to RS Production via the RS IoT 4G machine connector.

It's quick and easy to start measuring your machinery's energy consumption. The standard ampere meters connect seamlessly to RS Production via the RS IoT 4G machine connector.

When you can identify and address losses using much energy, you can make significant improvements towards your factory sustainability targets.

Harness the power of OEE and energy monitoring

It's time to take action and use OEE combined with energy monitoring. Doing so can propel your factory's success, contribute to a more sustainable future, and align with the United Nations' Sustainable Development Goals (SDGs).

A factory that uses its production resources efficiently will produce at a lower unit cost - both economically and sustainably. Don't let energy inefficiency drain your profitability.

Did we mention you can try without risk in your factory?

Take the opportunity to get a free demo and see for yourself – choose a time below for a web meeting with one of our experts so that you can try RS Production Energy in action in your factory.