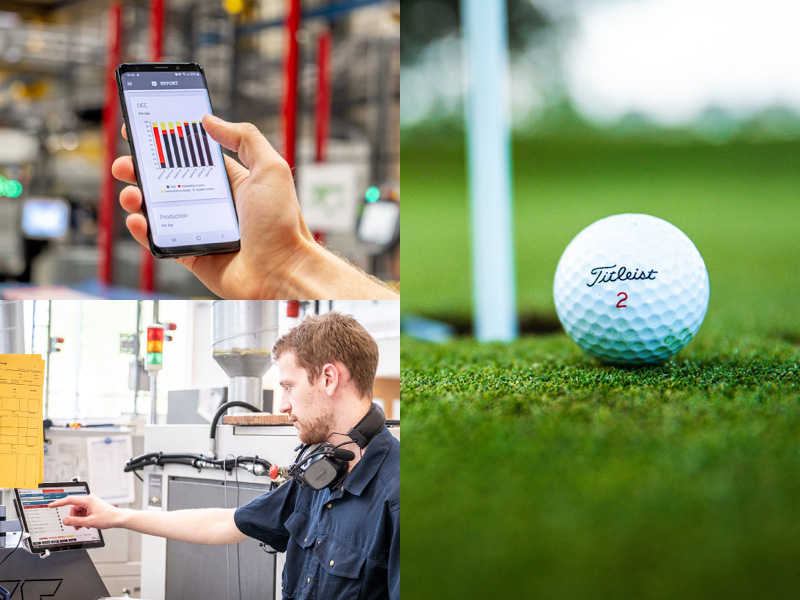

What looked like a beautiful Friday and 18 holes of worry-free golf has turned into an economic headache.

The investors eyes are on Tom, and Tom’s eyes see dollar signs.

The quality manager, Johanna, thinks she has a solution.

“What is RS Production?”

“We can't just rely on our ERP to give us everything and pray for miracles!”

“How much does it cost?”

Audible and inaudible questions fly around the room and in Tom’s head.

Johanna pours a coffee, clears her throat and asks where she should start.

“In what way does it complement our ERP? How can it reduce losses?” Gunilla, the production manager asks.

“Basically, our ERP supports us and connects us to our customers, but RS Production will support our operators and machines and connect them to us.”

“What do you mean?” Gunilla likes the sound of that. It’s time-consuming and frustrating to be in the middle of production and management constantly. Who will take on that role when she’s not at the factory (… at a wine tasting in Champagne)?

“Now we rely on our operators manually writing down events around the machines and telling us when something is wrong or slow or inefficient. They don’t benefit from our ERP at all.”

“Can’t we just teach them to use our ERP?” Tom is still wondering how the investors will respond to another purchase.

“Our machines and operators make us money, and our ERP won’t help them. RS Production will mean that all of us can make better decisions faster. We won’t need to wait for a financial report to see production or efficiency losses. It will be sent straight to our phones and laptops.

“So when we enter the factory, it hopefully won’t be silent and full of worried operators and question marks. The operators and we will be continuously updated and a step ahead of the production plan.

“We will be able to actively ensure and improve production every hour of every day on every shift.”

“OK,” says Tom. “That sounds great. But I need something else to tell them. How will it make us more attractive in 5-10 years?”

Tom gets into his car after a long day of long meetings and growing headaches.

He calls Johan and tells him he’ll meet him on the first tee, not on the driving range as planned.

Johan tells him he’ll give him a free mulligan to cheer him up a little.

On the phone, Tom asks if Johan knows anything about RS Production.

“Don’t tell me you’re not already using it?” laughs Johan. “No wonder you’re always stressed.”

Next installment:

- Will Tom need his mulligan?

- How does Johan use RS Production in his factory?

- Will Johan help Tom increase production and reduce his handicap?

Meanwhile, please download the first chapter of our new series "Top 7 challenges factories face and why your ERP can’t help you".

Meanwhile, please download the first chapter of our new series "Top 7 challenges factories face and why your ERP can’t help you".