RS Production® is AI-powered and designed to help you get up and running in minutes

-

See the difference in 45 days. Risk-free trail

-

Remove production waste and lower CO2 use

-

Automatic downtime detection and unit count

-

Connect 5 machines in 1 hour

-

From only €2,5 a day/machine*

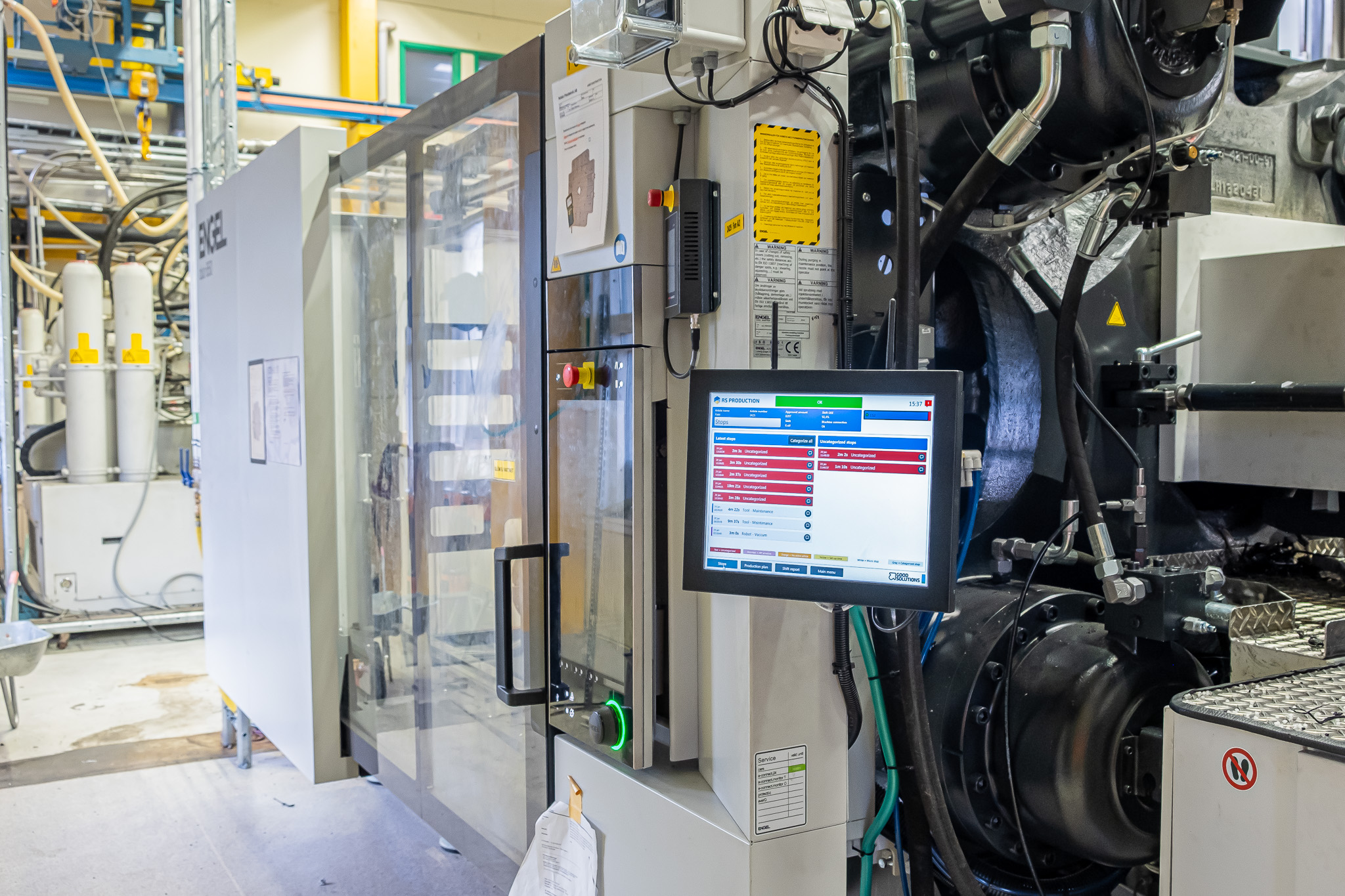

Position RS IoT hardware on your machine

Quick setup and connection

Our AI learns your articles cycle times

Frequently Asked Questions (FAQs) about RS Production® OEE for Injection Moulding

What business value does RS Production OEE offer to injection moulding manufacturers?

RS Production OEE enhances operational efficiency, reduces downtime, and increases profitability by optimising machine availability and performance. Our case studies, like Nolato Gota and Fristad Plast, demonstrate up to 35% improvement in factory efficiency and substantial output gains without additional capital investment.

How do I get started with RS Production OEE?

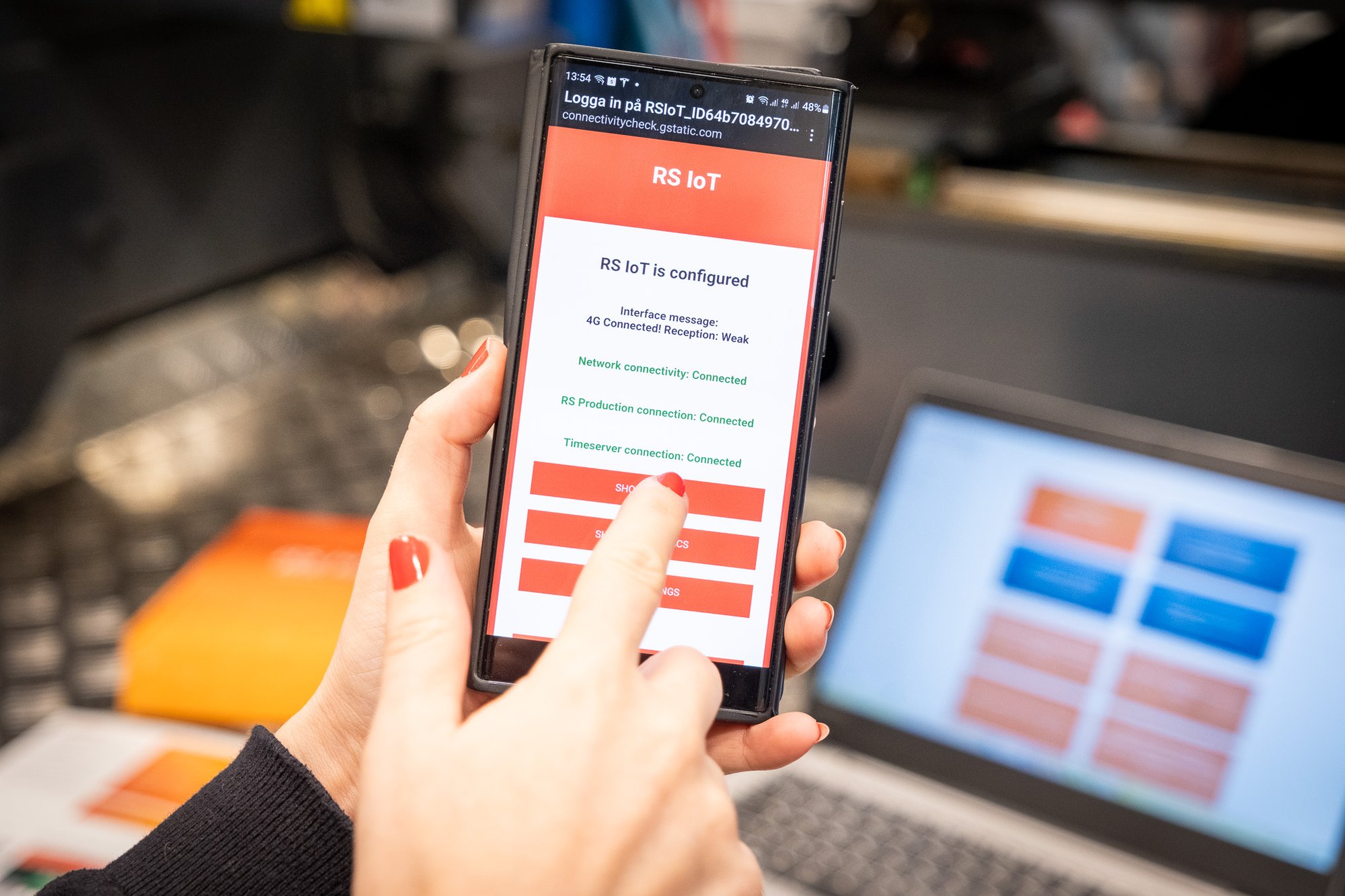

- Place the RS IoT device on a part of the injection moulding machine that you feel vibrating during a cycle.

- Set up the device using your smartphone to connect it to the RS Production OEE cloud over 4G.

- Allow the device up to 10 minutes to identify the machine's article cycle time.

What are the costs involved in implementing RS Production OEE?

From € 2,5 day/machine for RS Production OEE Pulse on 20 injection machines.

However, costs vary based on the scale of implementation and the specific needs of your manufacturing setup.

We offer a risk-free trial to help you assess the value of RS Production OEE with no upfront investment. For detailed pricing, booking a consultation with our experts is recommended.

How does RS Production OEE integrate with existing systems?

RS Production OEE integrates with various ERP systems such as IFS, SAP, M3, Jeeves, Monitor, Dynamics, and more.

Integrations can, for example, facilitate automatic updates on orders and stock, ensuring real-time data flow and enhanced decision-making across your production operations.

Can RS Production OEE help reduce CO2 emissions in my manufacturing process?

Absolutely. By improving machine efficiency and reducing waste, RS Production OEE optimises your production process and significantly reduces CO2 emissions per unit. This helps you achieve your sustainability goals while maintaining high profitability.

Try and see the difference in 45 days. Risk-free

That's why we offer a no-risk trial that lets you experience the benefits firsthand. Start with 5 machines and discover how plastic manufacturing optimisation and rubber production improvement can redefine what you thought possible.

Try for free. Opt out if you're not happy

See results in 45 days or opt out. Your commitment is matched only by our confidence in delivering excellence.